We found a great manufacturer to partner with on this project, and they sublimation printed and sewed a test article for us with the graphic we designed. The fabric is super comfortable and the print looks amazing! Now it’s time to stretch its limits.

A piece of clothing so comfortable and awesome that you want to wear it all the time needs to be able to hold up to any activity you decide to do in it. Within the diverse realms of bouldering, road cycling, yoga, and dancing, we’ve been very happy so far with these leggings.

- Climbing: the polyester/spandex blend rebounds to its original shape even after extended wear. It was also the most-discussed item we’ve ever tested in a gym – no shoe prototype has ever started so many conversations! Maybe unusual shoes just are harder to talk to a stranger about than saying, “I love your leggings!”

- Cycling: the fabric weight was perfect for a coastal California ride.

- Yoga/dance: the leggings stretch gently with your motion and stay opaque when sized properly.

We’re excited to continue testing these SFTights to learn how they perform over time.

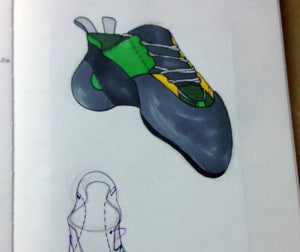

Some of the people who stopped by the SFT table had great input on one of my designs, and there was so much excitement about this concept that I decided to go ahead with a prototype.

The prototype pair of shoes was finished just in time for us to head to Owens Valley. Dan has been testing them all week, and he’s very happy with how they fit and the tension properties of the shoe. When we return to the shop, I’ll build a second version with some pattern updates for greater comfort and stretch management.

The SFT crew was out field testing in Nevada, and we documented the trip, hoping to use some of the footage in the short video I’ve been working on. While this particular problem didn’t fit into the main video that I’m crafting, we had too much fun on it to just consign the video to a hard drive.

Film is a great medium because even the scraps can be repurposed into little stories like this – it inspired me to find more ways to use “scrap” material from everywhere in our process.

]]>

By comparing how much weight (based on the volume of water) swatches could hold, I determined which adhesive was best for the SFT shoes and the optimal procedure for curing the adhesive.

Dan was finally happy with how the toebox shape felt - a symptom of getting the rubber patterns and application process dialed in. I believe his words were, "Dang son, I want a pair of these," mumbled as he pulled the shoe on the second time. Three of the gym's staff members were kind enough to try on this prototype; their feedback was also positive, citing toebox shape as well.

The biggest hurdle overcome in this prototype was proving out a new bearing design. The adjustment strap of the shoe currently runs from the instep side of the shoe to a "bearing" under the toebox sole, and then to the ladderlock on the outstep of the shoe. Previous bearings tended to become misaligned from the force vector of the adjustment strap, resulting in high stresses in the materials holding the bearings. In Dan's first shoe, these stresses (which are proportional to the climber's weight) were high enough to tear the bearing retention material.

Having seen what happens when a misaligned bearing is subjected to high loading, I sought to design a bearing that would remain aligned or self-align. Since this part was critical, I didn't want to finish the all-lasercut prototype with out it, but that pushed back the completion of the prototype by about a week. A lesson in supply-chain management was learned (most of the delay came from waiting for endmills of the appropriate size to arrive in the mail), and the bearing performed flawlessly last night.

Last week, 11 volunteers in Cambridge and Worcester, Massachusetts tried on and climbed in the two pairs of suede prototypes SFT currently has. We would have loved to have more people give us feedback, but testing was limited to finding climbers who fit the two sizes we currently have.

Last week, 11 volunteers in Cambridge and Worcester, Massachusetts tried on and climbed in the two pairs of suede prototypes SFT currently has. We would have loved to have more people give us feedback, but testing was limited to finding climbers who fit the two sizes we currently have.

The feedback we received has been invaluable, both in terms of encouraging and inspiring us and in highlighting three major areas that need revision (as well as several smaller points that can be improved). What was most impressive was the general consistency in comments between many climbers. Multiple climbers, though separated by testing sessions and geography, said:

1. they would like to feel more support in the arch,

2. the shoe's asymmetry range was larger than necessary, and

3. one's toes can still flex more than desired in the aggressive position. Additionally, over half of the climbers stated that the shoes were very comfortable.

The most common reaction, however, was to immediately explore the flexibility of the shoes. As Mak pointed out, we'd "never seen climbers wiggle their toes so much!" Some trip highlights: One climber exclaimed, "oh yeah, this is totally useful!" while finding the exact perfect adjustment for his shoes before beginning an overhanging problem. While at WPI, several climbers sat down and held an impromptu brainstorming session about what they'd like to see in the next set of prototypes. SFT is extraordinarily lucky that a lot of climbers are the improve-it-on-the-fly duct-tape-carrying types, so they've always got ideas to contribute.

The most common reaction, however, was to immediately explore the flexibility of the shoes. As Mak pointed out, we'd "never seen climbers wiggle their toes so much!" Some trip highlights: One climber exclaimed, "oh yeah, this is totally useful!" while finding the exact perfect adjustment for his shoes before beginning an overhanging problem. While at WPI, several climbers sat down and held an impromptu brainstorming session about what they'd like to see in the next set of prototypes. SFT is extraordinarily lucky that a lot of climbers are the improve-it-on-the-fly duct-tape-carrying types, so they've always got ideas to contribute.

After some testing, adding friction back to the bearings in the system did not look promising. Instead, I machined a custom ladder lock (shown in silver in the image). This design has a third aperture for the webbing which eliminates the self-unlocking angle.

After some testing, adding friction back to the bearings in the system did not look promising. Instead, I machined a custom ladder lock (shown in silver in the image). This design has a third aperture for the webbing which eliminates the self-unlocking angle.

Slip-testing results which compare the off-the-shelf ladder lock (shown in gold in the image) to the custom ladder lock are documented in the graph below.

]]>

With the new prototypes Ray helped us build, we've moved from proof-of-concept to design optimization and user feedback.

With the new prototypes Ray helped us build, we've moved from proof-of-concept to design optimization and user feedback.

Since the last post, I've simultaneously been drafting our patent application and modifying the Beta prototypes that fit me. Dan was able to take some nice shots of the Beta prototypes in action while I was testing them at Indian Rock in Berkeley this weekend. I'm proud to say that this pair of Betas is now passing 14 of the 17 tests which I've been using as a metric for prototype performance. This is up from the original 8 tests it passed when I first tested them a week ago.

Next steps:

When we have an official filing date from the USPTO, I plan to put up more detailed photos of SFT's prototype shoes to satisfy everyone's curiosity.

Once I've optimized the Betas that fit me, I'll modify the pair that fits Mak. Then I'll get in touch with everyone who's offered to try out prototypes and organize opportunities for some user feedback! This first round will necessarily be limited to volunteers who fit the two pairs of Betas available, so we'll play Cinderella. If you want to help out (and haven't already let me know) and think you'll fit the glass slipper, email sftclimbing@gmail.com with your contact information and foot size.

]]>

We're working on incorporating what we learned from climbing in these Frankenshoes into our next round of prototypes and modifications.

]]>