What we didn't expect (though perhaps it's obvious in retrospect) was the huge range in climbers' desires for how their shoes would fit. Because there are so many resources on how to fit shoes properly (gear reviewers discuss this, REI and other retailers discuss it, manufacturers put out information urging customers not to undersize too much, etc.), we built a fitting algorithm that was fairly rigid. It takes dimensions, makes assumptions about how much one's toes should be curled for a given last shape, and produces the last model that fits these inputs.

It turns out we shouldn't make that assumption about toe curl. For downturned shoes, there is a fair amount of consensus, but different climbers have in mind a HUGE range of different fit styles when ordering flat shoes. For different climbers, "flat shoes" can mean anything from all toes gently curled, to little toes curled/big toe flat, to all toes flat but touching the end of the shoe, to space beyond all the toes!

Clearly, a critical part of our ordering system will be a way for climbers to communicate exactly what they mean when they say "flat" or "downturned." We're working on how to help SFT customers make this preference clear. Some possible options are:

1. Have a trained person take the measurements for each order. This person could inspect a customer's feet in their previous shoes and make notes on the fit and special requests. (This would probably mean partnering with gyms or gear shops around the country and training their staff to become representatives for SFT).

2. Request that each customer photograph their feet in their previous shoes, using their thumb to indicate where the end of their big toe is in the shoe. These photographs would be submitted with the customer's measurements when they place their order.

3. Have a series of diagrams showing how feet can fit inside shoes, and allow the customer to choose the one that best describes their desired fit.

If you've got suggestions on what would be the most convenient way to communicate these preferences, we'd love to hear them. Feel free to comment below or to email lshumaker@sftclimbing.com.

]]>From concept sketch for a new closure system, to a quick prototype to check function, to shoes built with the system for a beta customer,

...in 7 days. Two years ago, I wouldn't have believed that SFT could pull that off. Thank you to all of you - friends, beta customers, suppliers - who've made this possible, and here's to the continual improvement of SFT's process to bring customized shoes to rock climbers!

]]>If you've been patiently waiting for the opportunity to get some SFT custom shoes, we're excited to finally invite you into our community of beta climbers!

Help us perfect our last algorithm by ordering a pair of custom shoes. Every climber who helps us now improves the speed and flexibility of our algorithm, but for that, we need you to be ready to give us feedback throughout the shoemaking and fitting process.

In gratitude for your help, beta custom shoes are $300 per pair and guaranteed to fit - we'll work with you until you're happy at no extra charge (learning your preferences and performance needs is how our algorithm improves).

For those of you who are living the dirtbag lifestyle or otherwise not sure if you can commit to submitting feedback, we plan to offer custom shoe orders with turn-around times of about a week for $400 at the end of June. For updates on availability, subscribe to our mailing list.

If you're interested now, thanks a ton! You can place your order by emailing beta@sftclimbing.com.

]]>Because everyone's feet are different, from a small pool of customers, we've been able to stretch the design to its limits. The same CAD model used for narrow, "Egyptian-toed" feet can be changed in 2 minutes to fit a person with wide feet and "Morton's toes." The toebox design has proved quite flexible.

However, fitting peoples' heels has been more difficult. After taking measurement after measurement, making visual comparison's of customers' bone structures, and building many prototypes to test various hypotheses, we made progress in determining how much narrower the last should be than one's foot tracing. However, each prototype seemed to fit a little differently around the Achilles tendon.

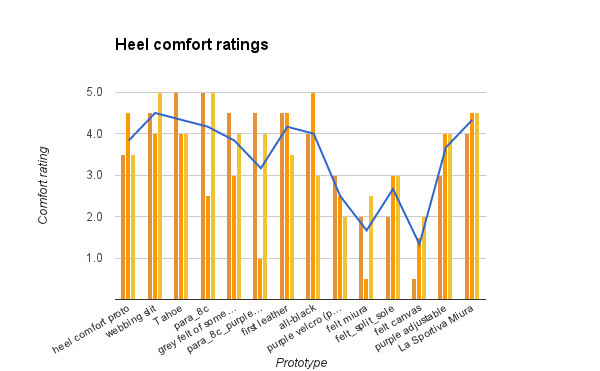

There must be some hidden weakness - sort of an Achilles heel, har har - in the last's heel and ankle design. Since we've built up quite a volume of prototypes, all with different materials, rand designs, and many other facets, I decided to conduct a survey of heel comfort versus all the variables that might affect heel fit.

I selected 14 prototypes, 5 of which were adjustable, to try on and rate in terms of comfort. Then I collected data on heel angle, rand design, and six other variables and calculated correlation coefficients between these variables and the comfort ratings.

When calculating correlation coefficients, prototypes with a comfort rating standard deviation of greater than 0.8 (graphically speaking: prototypes where the average rating differs greatly from the three samples) were not included.

The correlation coefficients indicated that heel stiffness was the variable with the greatest effect on heel comfort, followed by heel angle and whether or not the heel rand was continuous. The other variables measured were not significantly correlated to heel comfort.

SFT's most recent shoes built for customers have drawn on the information learned from this prototype survey, and our customers have noted how much more comfortable the heels are. One customer said, "The heel fits like a glove and this shoe looks absolutely fantastic."

Checking arch shape of the shoe under load.[/caption] It's time to put the rubber patterns into CAD.

]]>The most recent prototype made on Last 8 felt excellent during climb testing last week and passed the majority of tests I use to assess a prototype design, so I committed to grading Last 8 to Dan's size. Using scale factors derived from the slope of best fit lines from Army foot data (example graph below) and from Dan's foot measurements, I scaled up the CAD file, lasercut the new parts, and assembled Dan's last.

Now, I'm assessing methods for efficiently creating the graded patterns in 3D CAD and flattening them accurately.

]]> With the new prototypes Ray helped us build, we've moved from proof-of-concept to design optimization and user feedback.

With the new prototypes Ray helped us build, we've moved from proof-of-concept to design optimization and user feedback.

Since the last post, I've simultaneously been drafting our patent application and modifying the Beta prototypes that fit me. Dan was able to take some nice shots of the Beta prototypes in action while I was testing them at Indian Rock in Berkeley this weekend. I'm proud to say that this pair of Betas is now passing 14 of the 17 tests which I've been using as a metric for prototype performance. This is up from the original 8 tests it passed when I first tested them a week ago.

Next steps:

When we have an official filing date from the USPTO, I plan to put up more detailed photos of SFT's prototype shoes to satisfy everyone's curiosity.

Once I've optimized the Betas that fit me, I'll modify the pair that fits Mak. Then I'll get in touch with everyone who's offered to try out prototypes and organize opportunities for some user feedback! This first round will necessarily be limited to volunteers who fit the two pairs of Betas available, so we'll play Cinderella. If you want to help out (and haven't already let me know) and think you'll fit the glass slipper, email sftclimbing@gmail.com with your contact information and foot size.

]]>Why? We're developing a new kind of climbing shoe - one that adapts to the wearer's style instead of cramping it. It will redefine the standard for performance and comfort for climbing footwear.

As we reach milestones in the development process, we'll post updates here. If you have any questions or comments, don't hesitate to contact us. To all of you who have already expressed your support, thanks!

Cheers,

Laura and Mak

]]>