If you’re still looking for custom climbing shoes, consider trying the following:

kN Climbing - fully custom, Las Vegas, NV. I can vouch for the quality of their work, having ordered early prototypes from them.

evolv - their XY program will let you order two differently sized shoes, but they don't do other customizations.

Roundy Boots - located in the US, haven't seen their work.

In Europe:

Le Chausse Montagne - located in France, haven't seen their work.

If none of these options are nearby, another way to find custom shoemakers near you might be to call local resolers and ask if they ever do custom projects or know shoemakers who do.

SFT Climbing's legacy:

I'm really proud of what we've been able to do - making custom climbing shoes more widely available - the fact remains that continuing to run SFT Climbing isn't a good idea for me personally.

However, I will be keeping this website up as a sort of museum (but all of our shoes will remain "sold out"). When I started making climbing shoes, it was difficult to find information on how to do design and make shoes. Lots of resolers, climbers, and designers were happy to share their knowledge with us, but it was still a long, hard journey. By way of giving back to the community, I'd like to volunteer my experience to anyone who's curious about the shoemaking industry and the unique way we practiced it here at SFT. Have a look around the site (lots of our design process is documented on the rest of the blog) or feel free to reach out if you ever have any questions at service@sftclimbing.com.

Thanks for supporting us, and warmest regards,

Laura Shumaker

(Founder and Lead Designer)

We found a great manufacturer to partner with on this project, and they sublimation printed and sewed a test article for us with the graphic we designed. The fabric is super comfortable and the print looks amazing! Now it’s time to stretch its limits.

A piece of clothing so comfortable and awesome that you want to wear it all the time needs to be able to hold up to any activity you decide to do in it. Within the diverse realms of bouldering, road cycling, yoga, and dancing, we’ve been very happy so far with these leggings.

- Climbing: the polyester/spandex blend rebounds to its original shape even after extended wear. It was also the most-discussed item we’ve ever tested in a gym – no shoe prototype has ever started so many conversations! Maybe unusual shoes just are harder to talk to a stranger about than saying, “I love your leggings!”

- Cycling: the fabric weight was perfect for a coastal California ride.

- Yoga/dance: the leggings stretch gently with your motion and stay opaque when sized properly.

We’re excited to continue testing these SFTights to learn how they perform over time.

Sometimes you just have to play a little. We’ve been working on a side project – a new SFT product that started as a pun. Care to guess what it might be?

]]>

Some of the people who stopped by the SFT table had great input on one of my designs, and there was so much excitement about this concept that I decided to go ahead with a prototype.

The prototype pair of shoes was finished just in time for us to head to Owens Valley. Dan has been testing them all week, and he’s very happy with how they fit and the tension properties of the shoe. When we return to the shop, I’ll build a second version with some pattern updates for greater comfort and stretch management.

]]>

Ever since the first SFT beta shoes were shipped, we’ve been branding the logo into the leather and then hand-inking it for contrast. These branded logos look lovely right out of the box, but the ink doesn’t last past the first resole. Maybe fine for the first prototypes, but clearly, it was time to reconsider the logo process.

Thinking about the logo as a subassembly (what kind of components generate the logo) rather than as a process to be improved (how do we make our ink more durable – that we already experimented with) opened up the possibilities. After considering design options, we decided on woven fabric labels. Unlike most of our other manufacturing steps, woven labels are a component best sourced from one of the many companies that already specialize in this. Last step: find a supplier to partner with – the first component-level link in our supply chain.

We found that the Dutch Label Shop offered the space for creativity and the commitment to durability that SFT wanted for our new woven labels. The first order turned out great, and we’re proud to incorporate them into our shoes.

]]>The SFT crew was out field testing in Nevada, and we documented the trip, hoping to use some of the footage in the short video I’ve been working on. While this particular problem didn’t fit into the main video that I’m crafting, we had too much fun on it to just consign the video to a hard drive.

Film is a great medium because even the scraps can be repurposed into little stories like this – it inspired me to find more ways to use “scrap” material from everywhere in our process.

]]>The patent examiners can help you re-write your claims.

But only on the basis of what's in the original application document. So make your description as broad as Uncle Henry after he's cleared the Thanksgiving leftovers before surrendering your baby invention to the trained and caring hands of the USPTO.

]]>Bottom line, I’ve been staring at detailed footage of the build process for a single pair of shoes for hours. Days.

And it’s paid off. Not just because it’s coming together into a sweet little video, but because editing the video made me realize some things about how SFT builds shoes right now.

For example, no one wants to sit through watching glue dry on rubber for 20 minutes before I reactivate it to apply the rand to the shoe upper, so obviously that all gets cut from the raw footage. And everything that has to be cut, I’ve been looking at through the lens of process optimization – if I can be working on another component during that downtime, I can become more efficient as a craftsperson.

Another, less obvious lesson from video editing was how much time I spend with the glue container open. I’ve known for a while that the contact cement we use has a lifespan. I refuse to use glue over a couple of months old on components that see a lot of abrasion because an older glue bond has less peel strength than one made with fresh glue.

Since I’m constantly moving and conscious of my glue’s working time while painting it onto components, I assumed that the glue in the can wasn’t open to the air (and therefore aging) for longer than could be helped. It was shocking to see how much of the total video footage included an open can of glue! Fortunately, there’s a product called a cement pot that can help reduce the amount of glue exposed to air and the duration of that exposure, so I’ve finally purchased one. Maybe I’ll film another shoe assembly once I have the cement pot to check how much this improves the process and material usage.

While large factories have best practices and processes for process optimization, for me as a craftsperson building shoes at the same time as building SFT Climbing, there’s not always a lot of time for reflection on how everything gets done. But when I approach every task with both the immediate goal as well as how it fits into the larger picture in mind, I can almost always find some way to improve the overall process or product. Because we are all cross-function team members at SFT, manufacturing got to see itself in the mirror held up by marketing’s raw video footage, and our glue bonds will be stronger because of that.

]]>

We now offer 5.10 rubber as an option for the soles of SFT shoes!

]]>I just met a climber tonight Who told me, "Here's how to climb right your shoes will feel sweet when they're fit to your feet, and they're laced up So F*#king Tight."a more amorous one:

I once met a climber from Boulder Who had some freaking jacked shoulders I belayed her up and down helped her climb around, but all I really wanted was to hold her.some real advice:

Did you hear about the climber from Colorado? Who has such a strange motto: 'Climb safe, climb hard... rub your flappers with lard, and finish all your meals with an avocado.'for facing strange competition:

I once faced a climber from 'frisco Who was powered by purely Nabisco While not sure to believe him, To make sure I beat him, I lathered all the holds with Crisco!Which one would best prepare you for a 24-hour climbing competition?]]>

What we didn't expect (though perhaps it's obvious in retrospect) was the huge range in climbers' desires for how their shoes would fit. Because there are so many resources on how to fit shoes properly (gear reviewers discuss this, REI and other retailers discuss it, manufacturers put out information urging customers not to undersize too much, etc.), we built a fitting algorithm that was fairly rigid. It takes dimensions, makes assumptions about how much one's toes should be curled for a given last shape, and produces the last model that fits these inputs.

It turns out we shouldn't make that assumption about toe curl. For downturned shoes, there is a fair amount of consensus, but different climbers have in mind a HUGE range of different fit styles when ordering flat shoes. For different climbers, "flat shoes" can mean anything from all toes gently curled, to little toes curled/big toe flat, to all toes flat but touching the end of the shoe, to space beyond all the toes!

Clearly, a critical part of our ordering system will be a way for climbers to communicate exactly what they mean when they say "flat" or "downturned." We're working on how to help SFT customers make this preference clear. Some possible options are:

1. Have a trained person take the measurements for each order. This person could inspect a customer's feet in their previous shoes and make notes on the fit and special requests. (This would probably mean partnering with gyms or gear shops around the country and training their staff to become representatives for SFT).

2. Request that each customer photograph their feet in their previous shoes, using their thumb to indicate where the end of their big toe is in the shoe. These photographs would be submitted with the customer's measurements when they place their order.

3. Have a series of diagrams showing how feet can fit inside shoes, and allow the customer to choose the one that best describes their desired fit.

If you've got suggestions on what would be the most convenient way to communicate these preferences, we'd love to hear them. Feel free to comment below or to email lshumaker@sftclimbing.com.

]]>From concept sketch for a new closure system, to a quick prototype to check function, to shoes built with the system for a beta customer,

...in 7 days. Two years ago, I wouldn't have believed that SFT could pull that off. Thank you to all of you - friends, beta customers, suppliers - who've made this possible, and here's to the continual improvement of SFT's process to bring customized shoes to rock climbers!

]]>Because our last model is parametric (its geometry is determined by a stored set of equations and relationships), it can adapt to accommodate different variations of foot proportions. This video shows how the last shape changes for a 5% increase in length and a 22% increase in width across the ball of the foot.

]]>If you've been patiently waiting for the opportunity to get some SFT custom shoes, we're excited to finally invite you into our community of beta climbers!

Help us perfect our last algorithm by ordering a pair of custom shoes. Every climber who helps us now improves the speed and flexibility of our algorithm, but for that, we need you to be ready to give us feedback throughout the shoemaking and fitting process.

In gratitude for your help, beta custom shoes are $300 per pair and guaranteed to fit - we'll work with you until you're happy at no extra charge (learning your preferences and performance needs is how our algorithm improves).

For those of you who are living the dirtbag lifestyle or otherwise not sure if you can commit to submitting feedback, we plan to offer custom shoe orders with turn-around times of about a week for $400 at the end of June. For updates on availability, subscribe to our mailing list.

If you're interested now, thanks a ton! You can place your order by emailing beta@sftclimbing.com.

]]>

The most pertinent thing about SFT, for the Meetup audience, would be a discussion of how we are leveraging digital manufacturing techniques to bring customized shoes to climbers. Because climbing shoes fit so tightly and human feet vary so widely, SFT has had to rethink traditional shoe manufacturing so that our process can accommodate natural variations efficiently (i.e. to bring custom shoes to as many climbers as possible at the least environmental cost). We are pursuing digital manufacturing because we assume that the shoe fits the climber, instead of stuffing climbers into generic shoes.

When people say "digital manufacturing," almost everyone jumps to the idea of 3D printing the whole shoe, but right now (due to the materials available, print time, print volumes, etc.), that's not really feasible. Of course, "shoes" have been 3D printed, but they're stiff sculptures, not engineered tools that complement the wearer's biomechanics. Instead of trying force a product into the requirements of one limited manufacturing process, SFT believes in choosing materials and digital techniques suited to the product’s requirements.

When people say "digital manufacturing," almost everyone jumps to the idea of 3D printing the whole shoe, but right now (due to the materials available, print time, print volumes, etc.), that's not really feasible. Of course, "shoes" have been 3D printed, but they're stiff sculptures, not engineered tools that complement the wearer's biomechanics. Instead of trying force a product into the requirements of one limited manufacturing process, SFT believes in choosing materials and digital techniques suited to the product’s requirements.

Nike and Adidas' knitted upper method is a great example of leveraging a digitally controlled machine to obviate the need for part tooling. Here, making rule dies for pattern cutting, cutting the patterns out of sheet stock and wasting some of it, and then stitching it all together has been eliminated or minimized. Critically, by eliminating the need for expensive tooling specific to each shoe style and size, knitted uppers can reduce the pressure to mass-produce shoes.

The shoemaking process has many such pressure points where traditional techniques have relied heavily on fixed tooling. For example, lasts are cut in every size (and left and right) for a specific shoe design. Cutting so many lasts can be expensive upfront, so many manufacturers have stopped offering different widths to reduce tooling costs. However, with a parametric last model and a laser cutter, SFT can make quick-turn, durable, and recyclable custom lasts. When a customer places an order, the last model is reconfigured in a couple of minutes to match the critical features of their foot. In another 2 hours, we can complete a last that's ready to build a shoe on. By making our lasts on demand, we aren’t wedded to a precut scale of sizes. By making the lasts quick-turn and recyclable, we can make lasts only when needed, storing the digital information necessary to create them.

Besides the lasts, there are lots of other steps in making climbing shoes which need rethinking to better support customization and to reduce our industry's waste and reliance on outsourced labor. That's the stuff that wakes me up in the middle of the night (luckily there's a whiteboard next to the bed to brainstorm on). SFT's long-term commitment to digital manufacturing is what I wanted to communicate to the people at the hardware meetup. In the process of compiling my thoughts before speaking there, I realized that SFT has a vision, a manifesto, if you will. This vision of what we can give to the climbing community is what drives us forward:

SFT Climbing leverages digital manufacturing techniques to make shoes that fit real feet. We're applying the right technology to each step in the manufacturing process so that we can do what's best for climbers and for the world that we climb in.

The SFT lightning talk on youtube:

]]> ]]>

]]>

Because everyone's feet are different, from a small pool of customers, we've been able to stretch the design to its limits. The same CAD model used for narrow, "Egyptian-toed" feet can be changed in 2 minutes to fit a person with wide feet and "Morton's toes." The toebox design has proved quite flexible.

However, fitting peoples' heels has been more difficult. After taking measurement after measurement, making visual comparison's of customers' bone structures, and building many prototypes to test various hypotheses, we made progress in determining how much narrower the last should be than one's foot tracing. However, each prototype seemed to fit a little differently around the Achilles tendon.

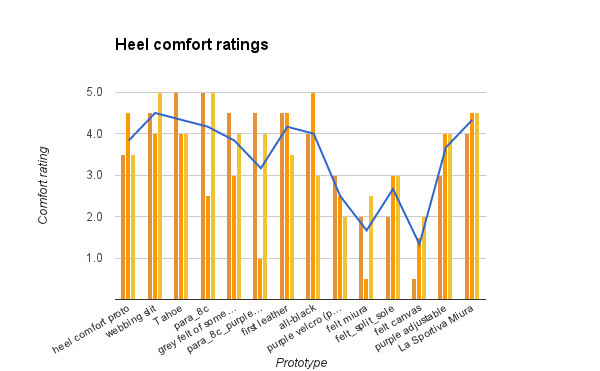

There must be some hidden weakness - sort of an Achilles heel, har har - in the last's heel and ankle design. Since we've built up quite a volume of prototypes, all with different materials, rand designs, and many other facets, I decided to conduct a survey of heel comfort versus all the variables that might affect heel fit.

I selected 14 prototypes, 5 of which were adjustable, to try on and rate in terms of comfort. Then I collected data on heel angle, rand design, and six other variables and calculated correlation coefficients between these variables and the comfort ratings.

When calculating correlation coefficients, prototypes with a comfort rating standard deviation of greater than 0.8 (graphically speaking: prototypes where the average rating differs greatly from the three samples) were not included.

The correlation coefficients indicated that heel stiffness was the variable with the greatest effect on heel comfort, followed by heel angle and whether or not the heel rand was continuous. The other variables measured were not significantly correlated to heel comfort.

SFT's most recent shoes built for customers have drawn on the information learned from this prototype survey, and our customers have noted how much more comfortable the heels are. One customer said, "The heel fits like a glove and this shoe looks absolutely fantastic."

This prototype was built to explore a new rand design. Instead of splitting the rand where the sole splits, the toe rand is a continuous arch which connects to the heel rand above the shoe's mid-section. This rand geometry produces a more torsionally stable toebox.

]]>

Having zig-zag stitch capability is critical to making comfortable climbing shoes because it enables abutted seams. The main seam on rock climbing shoes crosses the ends of one's toes right where the shoe touches the rock. With a normal, non-abutted seam, this would mean there would be more than 2 layers of fabric between one's toes and the rock, right where the most sensitivity is required. Abutted seams don't have any overlap, so the entire shoe has only one fabric thickness and no bulky seams.

]]>

SFT shoes, made for your unique feet. This prototype is sized based on the wearer's foot width, length, and height. And it can cost less than half as much as a custom shoe.

Many climbing friends brought up what a pain it is to find shoes that fit properly. If you or someone you know wants to help me fix this, please fill out these 7 questions.

]]>Since the new last I'm working on is not based on a 3D scan, it's likely the most complex geometry I have ever created CAD for. Consequently, wrapping my head around it has required a lot of drawing board time. Pencil and paper is much more flexible than the rigid definitions of a CAD program when initially hashing out complex curves and has the up side of making me feel like a 1950s engineer.

In light of Kevin's suggestions, I've started planning a new CAD model which will combine the best points of my current lasts and the things I learned from visiting Leahy Custom Hiking Boots.

By comparing how much weight (based on the volume of water) swatches could hold, I determined which adhesive was best for the SFT shoes and the optimal procedure for curing the adhesive.